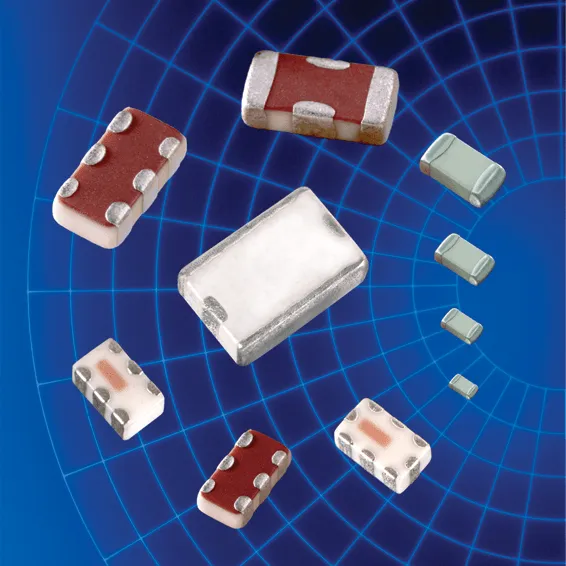

Integrated Passives

Johanson Technology designs and manufactures a line of small, highly stable and integrated RF ceramic components manufactured with a proprietary LTCC (low temperature co-fired ceramic) process and materials. These components operate and thrive over several RF bands from 400MHz to 30GHz covering Cellular, DECT, WLAN, WiMax, all ISM, Bluetooth, 802.11 (a,b and g) and GPS applications.