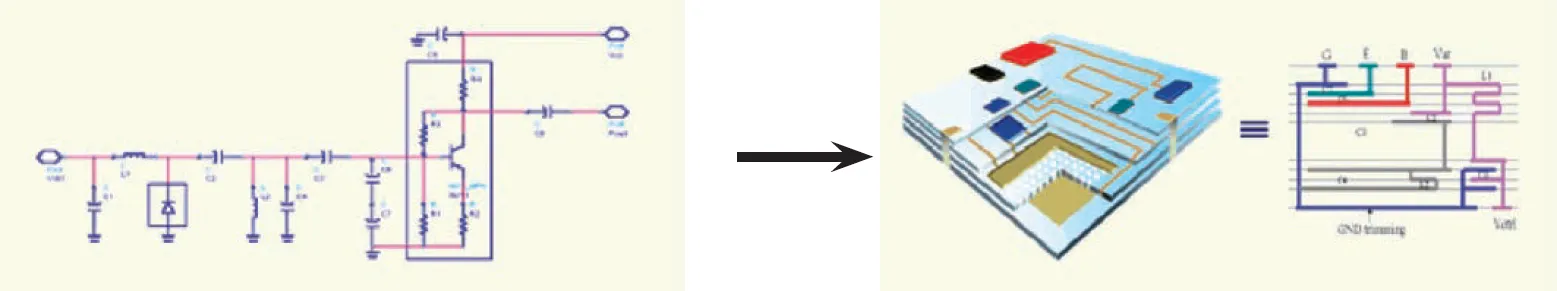

Custom LTCC Module Foundry Service

Johanson Technology has the capability to produce a wide range of application specific components for wireless communication such as Diplexer Switch, VCO, PA and highly integrated RF modules using LTCC (Low Temperature Co-fired Ceramic) technology. We offer extensive expertise using an internally developed LTCC tape system.

| Design Rules | Standard (mm) | Advanced (mm) |

|---|---|---|

| (A) Via Hole Dia | 0.125, 0.18 | 0.06 (min) |

| (B) Via Cover Dot Dia | >= Via + 0.03 | Via + 0.02 |

| (C) Via Center Spacing | >= 0.20 (for 0.07 via) | 0.18 (for 0.05 via) |

| (D) Via Cover Dot Edge to Line Edge | > 0.10 | > 0.08 |

| (E) Line Width | >= 0.10 | >= 0.05 |

| (F) Line to Line Spacing | >= 0.10 | >= 0.08 |

| (G) Line Center Spacing | >= 0.18 | >= 0.13 |

| (H) Outside Edge to Via Center | >= 0.15 | >= 0.135 |

| (I) Line Over Outside Edge for Cutting | >= 0.05 | >= 0.05 |

| (J) Outside Edge to Line Clearance | >= 0.10 | >= 0.10 |

| (M) Buried Ground Plane Spacing | 0.10 | >= 0.10 |

| (N) Feed thru Spacing | 0.15 | >= 0.10 |

| Substrate thickness | 0.5 to 1.6 | 0.3 to 2.4 |

| Number of Layers | Up to 20 | Up to 30 |

| LTCC Tape Characteristics | JTI |

|---|---|

| Dielectric Constant (@ 3GHz) | 7.5 |

| Dielectric Loss (@ 3GHz) | 0.33% |

| TCE (25-300°C) (ppm/°C) | 4.7 |