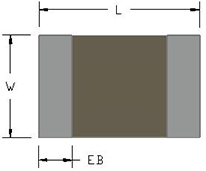

Capacitor PCB Pad Layout Recommendations

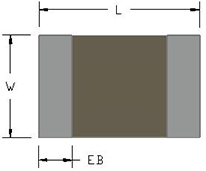

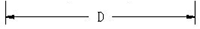

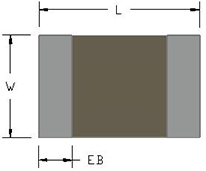

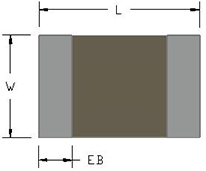

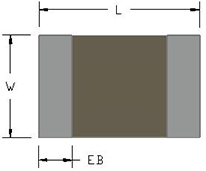

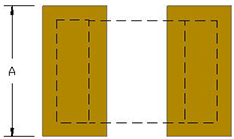

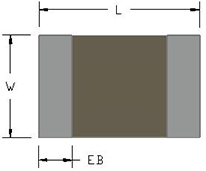

Solder pad design, solder application, and component placement are important elements of the soldering process. Excessive transfer of thermal or mechanical stresses to the MLC can result from oversized solder fillets. Nominal pad designs suitable for the solder reflow process are displayed in the interactive land pattern generator. These guidelines represent a starting point in Printed Circuit Board (PCB) design. For further information on the land pattern design, refer to the standard IPC-SM-782A “Surface Mount Design and Land Pattern Standard” published by the Institute for Interconnecting and Packaging Electronic Circuits (www.ipc.org).

Component Placement Considerations and Pitfalls

Solder pad design, solder application, and accuracy of component placement each must be considered when laying out circuits. This is especially true for RF and microwave circuits where incorrect or asymmetrical deployment of these parameters can lead to serious high frequency performance degradation. Designers beware. IPC-SM-782 is an excellent reference document for optimum soldering of components. However, blindly following this standard can lead to less than optimum high frequency performance and or high voltage issues. If you are not concerned with RF performance or high voltage requirements, Johanson recommends that designers follow this standard (IPC-SM-782). However, for those concerned with RF performance, we recommend a smaller land pattern (solder pad).

EIA (mm)/ Johanson Series

Surface Mount Capacitors

0201 / R05

0.015

(0.381)

0.011

(0.2794)

(0.254)

(0.254)

0.013

(0.3302)

0402 / R07

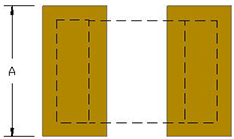

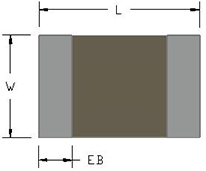

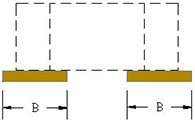

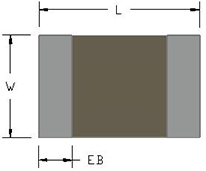

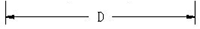

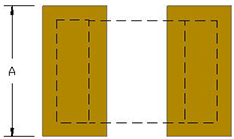

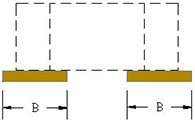

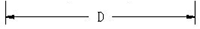

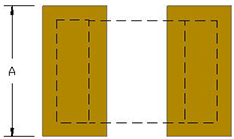

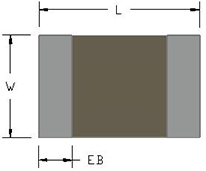

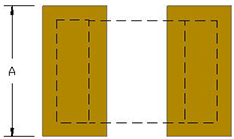

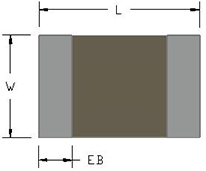

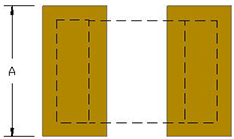

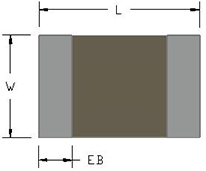

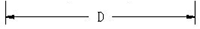

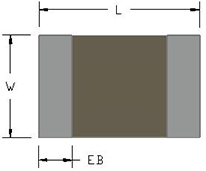

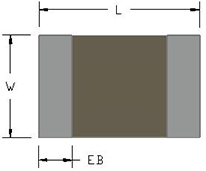

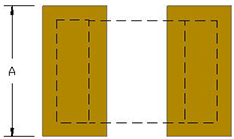

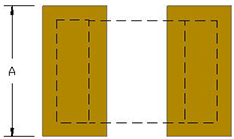

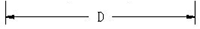

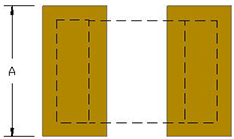

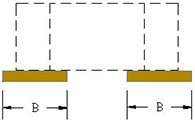

Top View (Component)

0.022

(0.5588)

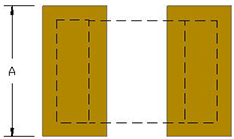

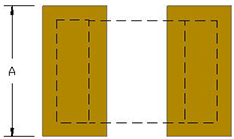

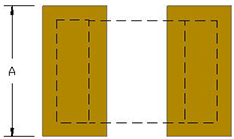

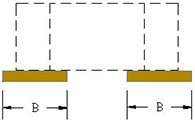

Top View (Pad Layout)

0.028

(0.7112)

0.023

(0.5842)

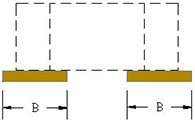

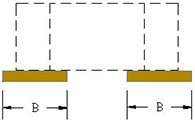

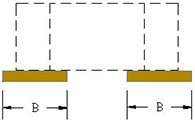

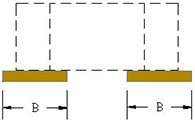

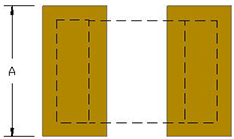

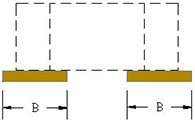

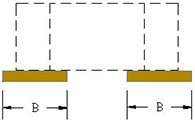

Side View (component)

0.025

(0.635)

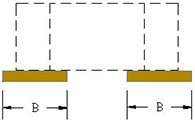

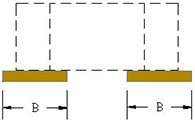

Side view (Pad Layout)

(0.3683)0.012

(0.3048)

(0.3683)0.012

(0.3048)

0603 / R14

Top View (Component)

0.032

(0.8128)

Top View (Pad Layout)

0.042

(1.0668)

0.042

(1.0668)

Side View (Component)

0.035

(0.889)

Side View (Pad Layout)

(0.5842)0.020

(0.508)

(0.5842)0.020

(0.508)

0805 / R15

Top View (Component)

0.054

(1.3716)

Top View (Pad Layout)

0.070

(1.778)

0.053

(1.3462)

Side View (Component)

0.050

(1.27)

Side View (Pad Layout)

(0.889)0.024

(0.6096)

(0.889)0.024

(0.6096)

1111 / S42

Top View (Component)

0.103

(2.6162)

Top View (Pad Layout)

0.127

(3.2258)

Side View (Component)

0.102

(2.5908)

Side View (Pad Layout)

(0.9906)

(0.9906)

1206 / R18

Top View (Component)

0.065

(1.651)

Top View (Pad Layout)

0.089

(2.2606)

Side View (Component)

0.050

(1.27)

Side View (Pad Layout)

(1.016)

(1.016)

1510 / S41

Top View (Component)

0.098

(2.4892)

Top View (Pad Layout)

0.122

(3.0988)

Side View (Component)

0.065

(1.651)

Side View (Pad Layout)

(1.143)

(1.143)

1812 / S43

Top View (Component)

0.127

(3.2258)

Top View (Pad Layout)

0.167

(4.2418)

Side View (Component)

0.115

(2.921)

Side View (Pad Layout)

(1.5494)

(1.5494)

1808 / R29

Top View (Component)

0.085

(2.159)

Top View (Pad Layout)

0.125

(3.175)

Side View (Component)

0.085

(2.159)

Side View (Pad Layout)

(1.5367)

(1.5367)

1825 / S49

Top View (Component)

0.250

(6.35)

Top View (Pad Layout)

0.290

(7.366)

Side View (Component)

0.140

(3.556)

Side View (Pad Layout)

(1.6764)

(1.6764)

2211 / R30

Top View (Component)

0.110

(2.794)

Top View (Pad Layout)

0.150

(3.81)

Side View (Component)

0.115

(2.921)

Side View (Pad Layout)

(1.5367)

(1.5367)

2220 / S47

0.207

(5.2578)

0.247

(6.2738)

0.150

(3.81)

(1.6764)

(1.6764)

2225 / S48

0.322

(8.1788)

0.262

(6.6548)

(2.1844)

(2.1844)

0.160

(4.064)

2525 / S48E

2.80

(7.112)

0.250

(6.350)

(1.270)

(1.270)

0.150

(0.381)

3838 / S58

0.434

(11.0236)

0.380

(9.65)

(2.286)

(2.286)

0.170

(4.32)

RF Performance

For good RF performance, engineers designing PCBs should consider the following recommendations for Johanson Passives:

- Pad Size

- Johanson recommends smaller pad size when compared to the IPC standard. This is done to achieve a compromise between the best RF performance and optimum solderability.

- Large pad sizes like those recommended by the IPC-SM-782 standard will have RF impedance effects (which can be negative)

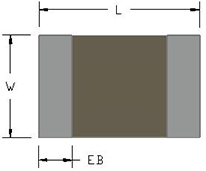

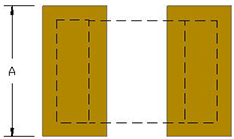

- Pad Symmetry

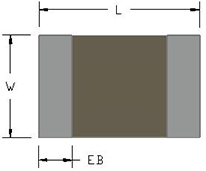

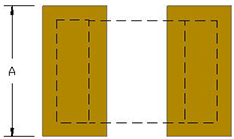

- Symmetrical land patterns (pads) are recommended to achieve better RF performance and reduce the likelihood of tombstoning

- Solder Fillet

- Solder fillet size can shift impedance at microwave frequencies. Johanson recommends smaller size fillets and consistent size fillets. Large wavelengths tend to be more forgiving with excess solder. Fillets at higher frequencies (very small wavelengths) are much more affected by poor soldering methods. Johanson recommends that the solder fillet be at the lower tolerances in order to minimize RF disruption.

- Controlling the solder fillet to the low side is an effort to minimize negative impedance effects that occur at higher frequencies.

- o Smaller solder fillets minimizes thermal and physical stresses

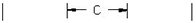

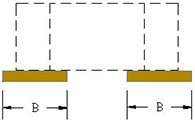

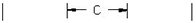

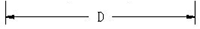

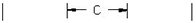

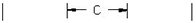

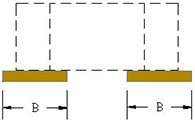

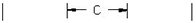

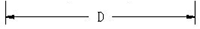

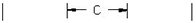

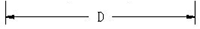

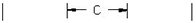

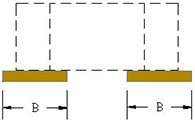

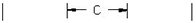

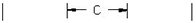

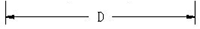

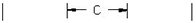

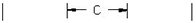

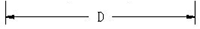

Safety Capacitors

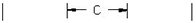

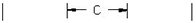

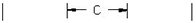

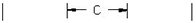

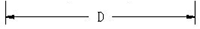

Caution for Safety Caps layouts – Layouts should meet the 3mm (0.1182”) or 4mm (0.1575”) minimum creepage distance between pads as required in the UL or TUV specifications. Here the creepage distance is defined by the “C” dimension in the layout above.