IPDs to Enhance TI Chipsets RF Front-End

Johanson Technology’s Integrated Passive Devices (IPDs), 0900PC15D0043001E and 2450PC15A0044001E are designed for the following Texas Instruments chipsets operating in +20 dBm transmit mode: CC1352P, CC1352P7, CC1354P10, CC1311P3, and CC1312P

These IPDs streamline design challenges by providing a simplified RF front-end solution. Each device replaces multiple discrete components, optimizing both space and performance, and is certified to meet FCC and ETSI standards. Here’s how each device enhances the efficiency, performance, and cost-effectiveness of RF design with Texas Instruments’ solutions.

Key Advantages of IPD Integration with TI

Miniaturization of Reference Design:

Johanson Technology’s IPDs integrate multiple passive components into a single EIA 0805 package (2.0 x 1.25 mm), enabling a drastic reduction in circuit footprint. This miniaturization is essential for compact IoT and wireless communication devices, as it allows for flexible PCB layouts and improved antenna placement. For instance:

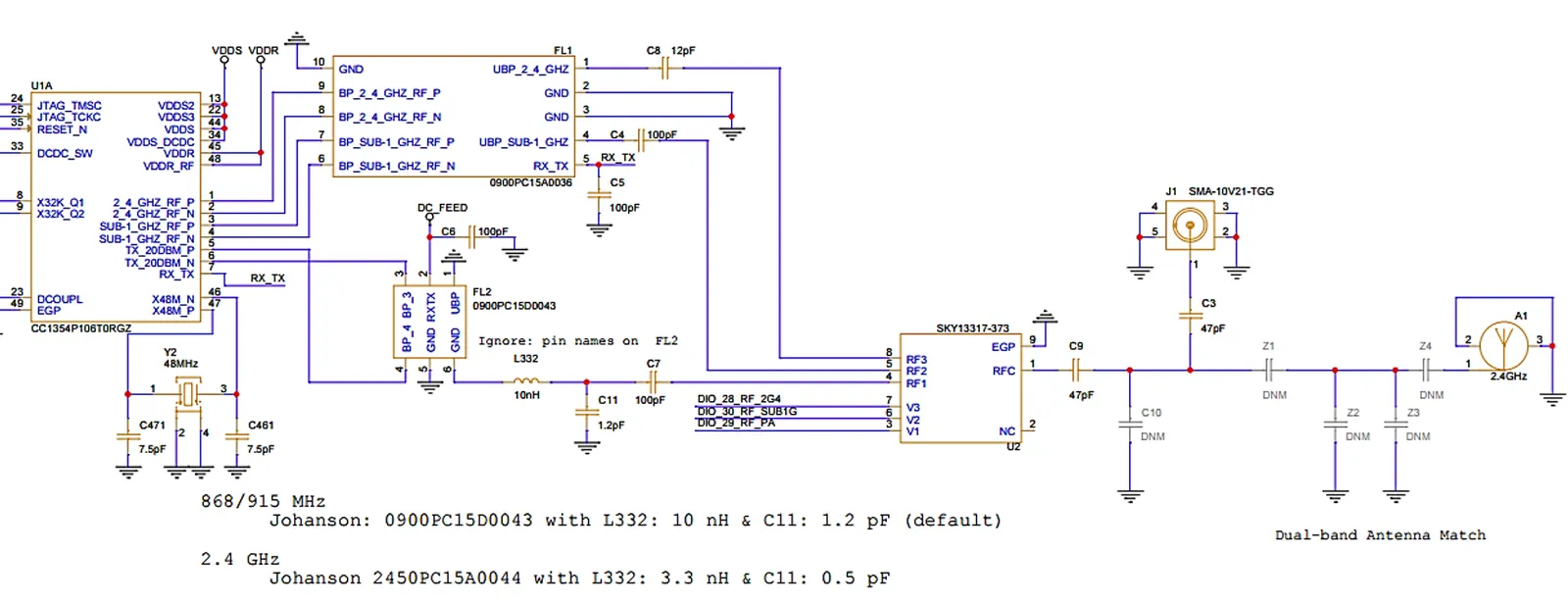

- P/N 0900PC15D0043001E replaces 11 L/C components, achieving efficient use of PCB space, especially in sub-1 GHz applications operating between 868 MHz and 928 MHz.

- P/N 2450PC15A0044001E replaces nine L/C components and is optimized for the 2.4 GHz band, making it ideal for applications such as WiFi and Bluetooth communications.

By incorporating these IPDs, engineers can achieve a smaller design footprint, accommodating additional features without increasing the overall device size. A complete product can be created with just s few components like the schematic below:

Faster Time to Market:

Using Johanson’s IPDs eliminates the need for multiple discrete components, streamlining the design and assembly process. This reduces engineering time in layout configuration and simplifies the component sourcing process. Engineers can deploy a verified RF front-end design swiftly, minimizing the testing and validation steps required for discrete solutions. With FCC/ETSI-compliant designs, these IPDs align with regulatory requirements, ensuring quicker certification cycles, ultimately speeding up time-to-market.

Semiconductor Manufacturer-Verified Performance (FCC/ETSI Compliance):

Both IPDs have been verified by Texas Instruments and are FCC/ETSI certified, providing a standardized performance baseline. This pre-qualification ensures reliable, consistent RF performance across different batches, enhancing the design's compliance without additional testing. This characteristic is invaluable in reducing RF variability and meeting the stringent performance requirements necessary for regulatory certifications.

Consistent RF Performance with No Variability:

Discrete components often introduce slight variations in RF performance due to component tolerances and manufacturing inconsistencies. Johanson’s IPDs eliminate this issue by integrating components with exact specifications and tighter tolerances, resulting in stable insertion loss, return loss, and phase/amplitude balance. For example:

• P/N 0900PC15D0043001E offers a typical insertion loss of 1.6 dB and phase difference of 180° ± 8°.

• P/N 2450PC15A0044001E maintains an insertion loss of 1.4 dB and amplitude difference as low as 0.9 dB.

This reliability in performance is crucial for applications requiring precise RF performance across all devices, supporting higher yields at contract manufacturing facilities (CEMs).

Cost-Effectiveness:

By replacing multiple discrete components with a single IPD, Johanson’s devices reduce the total component count, optimizing costs associated with BOM (bill of materials), assembly, and sourcing. These IPDs reduce assembly labor caused by multiplicity of L/C placement costs by simplifying the PCB layout, enhancing overall manufacturing efficiency. The reduced complexity allows manufacturers to allocate resources more effectively and streamline the assembly process, contributing to a more cost-effective RF solution.

Improved System Yields at Contract Manufacturing Facilities (CEMs):

A simplified design structure provided by these IPDs leads to higher yields during the assembly process at CEMs. Johanson’s pre-verified IPD designs reduce the potential for error in component placement and variability in RF performance, which are common with discrete component assemblies. With fewer components to manage, IPDs enhance production efficiency and quality assurance, supporting consistent manufacturing outcomes across high-volume production runs.

Applications:

Johanson’s IPDs are ideal for use in various Texas Instruments-based applications, including:

- Low-Power Wide Area Networks: 6LoWPAN, Amazon Sidewalk, IEEE 802.15.4, MIOTY, Matter, Proprietary, Thread, Wi-SUN, Wireless M-Bus, and Zigbee.

- Smart Meters and industrial IoT solutions requiring compact RF designs

- Wireless Sensor Networks supporting sub-GHz or 2.4 GHz bands'

- Security systems (smart locks), smart home devices

- WiFi and Bluetooth Mesh Applications in the 2.4 GHz spectrum, ideal for consumer electronics.

These devices cater to high-performance applications that benefit from reduced size, regulatory compliance, and streamlined production, providing an effective solution for modern RF front-end design.

Additional Resources:

P/N 0900PC15D0043001E Product Page

P/N 2450PC15A0044001E Product Page

Antenna Tuning and Optimization Services

Soldering and Handling Information

Ready to Start Your Design?

Contact our Applications Engineering Team for technical support.