Typical Soldering Profile (IPC)

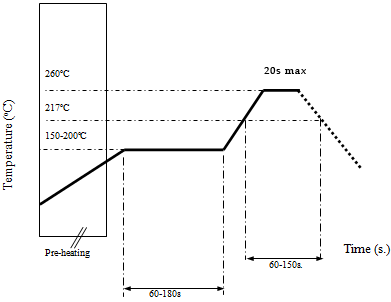

Typical Soldering Profile for Lead-free Process: RFCCs

Reflow Soldering:

Recommended Solder Paste: SAC 305 type

Number of allowed reflow cycles: 3max.

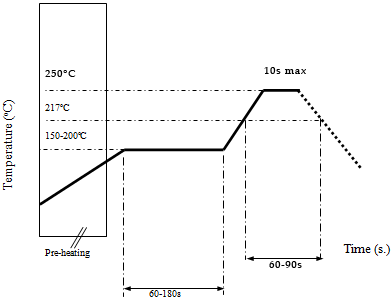

Typical Soldering Profile for Solderable Silver (Ag) Terminated Components:**

Reflow Soldering:

Recommended Solder Paste: SAC 305 type

| 0433BM15A0001 | 0868BM15C0001 | 0892DP15B1850 | 0892LP07A0136 |

| 0896BL14B050 | 0896BM15B0016 | 0900BL15A100 | 0900BL15C050 |

| 0915BM15A0001 | 1200BP44A575 | 1200LP41B0500 | 1200LP41C0500 |

| 1400BP41A0550 | 1810BP07B200 | 1900HP41B0500 | 1900HP41C0500 |

| 2025LP15A1225 | 1905BP18A0050 | 2450BM07A0004 | 2345FB39A0050 |

| 2450BL07A0100 | 2450BM15A0015 | 2450BM14E0007 | 2450BM15B0009 |

| 2450BP07A0100 | 2450BP08A0100 | 2450BP14D0100 | 2450BP14E0100 |

| 2450BP14F0100 | 2450BP15E0100 | 2450BP15F0100 | 2450BP15Q0100 |

| 2450BP39D100E | 2450BP15V0100 | 2450BP39D100C | 2450FB15A0100 |

| 2450BP39F100 | 2500BP15M400 | 2500FB16A0400 | 3350BP39A0500 |

| 2595FB16A0100 | 2600BP14M0200 | 3500FB39A0050 | 3600BP14M0600 |

| 3600BP15M600 | 0896FB15A0100 | 5400BP14A0950 | 5425BP15A1050 |

| 5525BP15B0750 | 2450BM08B0003 | 2450DP39K5400 | 2450DP39L5400 |

| 2450BL05A0100 | 2450FB15L0001 | 2450BM15B0003 | 0900PC15A0036 |

| 0845BL05A0100 | 0900FM15D0039 | 2025LP15B0145 | 2440AT62A0085 |

| 2440AT62B0085 | 2450BM14A0021 | 2450BP07C0100 | 2450BP08B0100 |

| 2450BP14G0100 | 2450BP14H0100 | 2450BP14J0100 | 2450FB14B0050 |

| 28R0BP44A1000 | 5235CR45A0180 | 5697CR45A0360 | 0900FM15D0039E |

| 5697CR45A0360E | 2440AT62A0085E | 2450FB15A050E | 5235CR45A0180E |

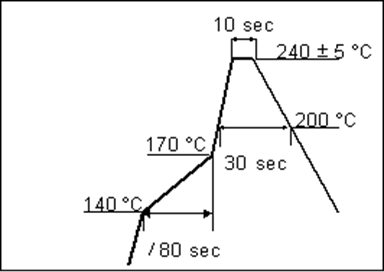

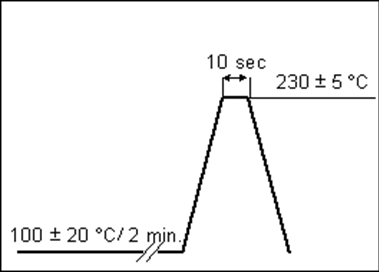

Typical Soldering Profile for Tin / Lead Terminated Components:

Flow Soldering

Reflow Soldering

Hand Soldering

Johanson Integrated Passive Components are intended for reflow soldering. When using a soldering iron, care must be used to avoid damaging the terminations and or, in some instances, the ceramic body. Three different issues can occur:

- Leaching of the termination

- Delamination of the termination

- Cracking of the ceramic body

The recommendation for hand soldering our integrated passives is 350°C for 3-5 seconds maximum using a relatively small soldering iron tip.